Among the many services we offer at kwality, offset printing is our most successful and popular one. Offset printing can print vast volumes of copy paper that is both easy to use and sustainable. Let us take you through this ancient printing technology, which has evolved over time to become one of the most extensively employed and economical printing technologies in today’s world.

The rich history of offset printing:

Lithography: Lithography was invented in the late 1800s as a low-cost method of reproducing artwork and theatrical materials. Lithography uses limestone presses to generate images that take advantage of the high viscosity of oil and water

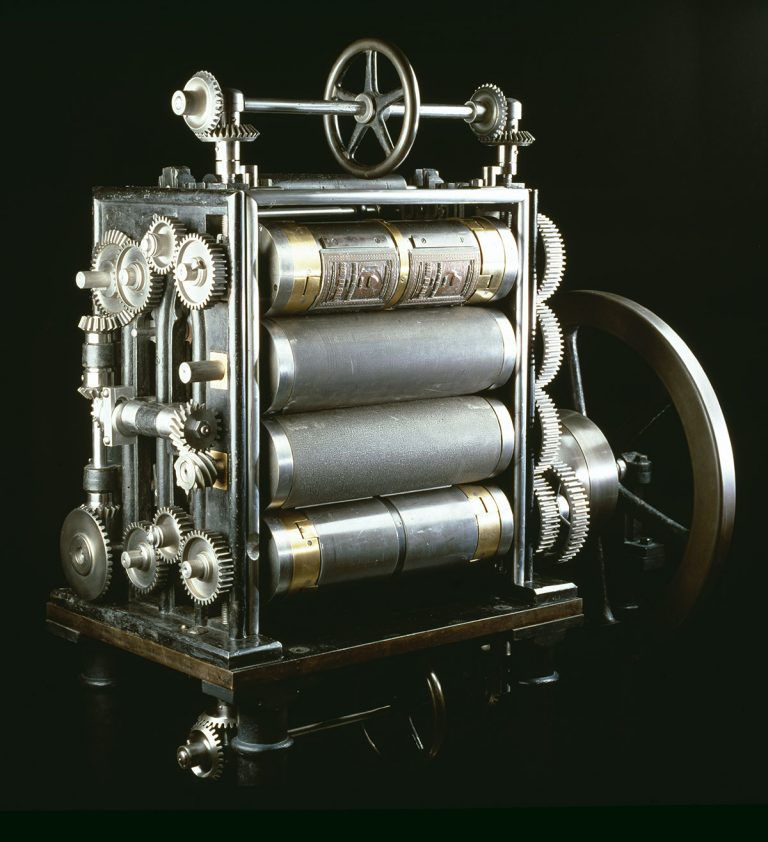

First rotary printing press: A cylinder is used in a rotary printing press to transfer the desired image to the printing surface. In 1790, the first patent for a rotary printing press was issued. Richard March Hoe expanded on the concept and invented rotary drum printing in 1843. The first lithographic printing press with a rotating offset.

Ira Washington Rubel: Ira Washington Rubel found in 1901, while operating the Barclay’s printing press, that printing on paper using a rubber roller produced a clearer, better resolution image. Previously, the machine used a cardboard-wrapped metal cylinder to print the image directly on metal.

20th Century offset printing: The offset printing press is still used today to print large quantities of any image or text. It’s still the ideal technique to print a large number of copies rapidly, effectively, and, most essentially, accurately.

offset Printing Process:

Offset printing is distinguished by the fact that water and ink do not combine during the printing process. Many alternative printing techniques make use of lasers, mesh, or letterpress. Pictures and phrases are placed on plates on which water and ink are applied. A rubber matting is used to roll over the images on the plates. The rubber mat is then placed on top of the paper stock, and the image is now ready to print. When using an offset printer, most, if not all, organizations will employ hues: cyan, magenta, yellow, and black. These tones provide rich undertones that bring the printed image to life.

What is the use of the rubber mat?

When offset printing first began in 1843, the image was transferred to a printed surface using a metal mat plate. Although this method worked, the image was not as clear as they had intended. When Ira Rubel, a paper producer in Nutley, New Jersey, forgot to put the mat in the printer in 1901, everything changed. The rubber mat was created as a result of this “error.” Rubel then realized that when a rubber mat was lifted, it generated a more precise picture than a metal mat plate, which was originally used in offset printing. Since then, offset printing has grown in popularity and is now one of the most widely used printing methods.

Applications of offset printing

Newspapers, periodicals, posters, pamphlets, brochures, and catalogues are all examples of commercial print that use offset printing. This printing method is not only economical but it also allows for the use of a range of printing materials, such as paper, card stock, and vinyl. You can also create a custom ink with the colors of your choice. When planning a marketing campaign and needing materials printed in your corporate hues, this is a terrific option to consider. The main benefit of offset printing is the print quality you will acquire. It gives you the best bang for your buck in terms of printing!

Offset color printing indeed serves a huge advantage for businesses that want to market their brand in a much more vibrant way. It is a must for brands that want their packaging to attract more people. Kwality’ s extensive hands-on experience makes it the ideal choice for brands that want to stand out from the competition.

Need labels and prints that speak for themselves? Get in touch with us to make your brand a brand like no other!